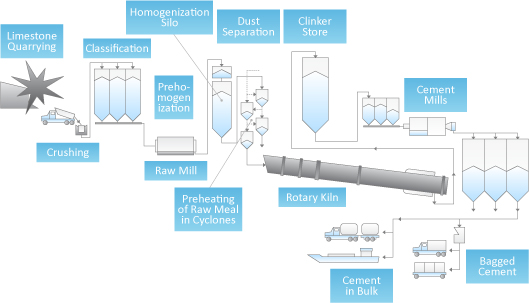

Our cement manufacturing process consists of many simultaneous and continuous operations using some of the largest moving machinery in manufacturing. Hundreds of sensors and computers allow the entire operation to be controlled by operators from a central control room at the production site.

There are four key stages in the production process of cement: (1) the crushing of raw materials; (2) the calcining and blending of raw materials; (3) the sintering of clinker; and (4) the grinding and blending of clinker to produce cement.

Crushing of raw materials

We transport raw materials such as limestone, gypsum, clay, flyash, pyrite cinder and slag to our crushing installations where they are refined to a fine compound.

Calcining and Blending of Raw Materials

The next stage can be either a wet or dry process. In the wet process, crushed raw materials are ground with water to form a mud-like mixture of slurry before being transferred into a kiln. In the dry process, crushed raw materials mixed in a certain proportion are ground and mixed without water to form a raw meal before being transferred into a kiln. The slurry or raw meal is then heated to up to about 2,700 degrees Fahrenheit (or about 1,450 degrees Celsius) in a huge cylindrical steel kiln, which chemically alters it.

Sintering of Clinker

After a series of complex physical and chemical reactions, the remaining elements unite to form a new substance called clinker. This clinker is discharged red-hot from the lower end of the kiln and cooled to a handling temperature. The heated air from the coolers is returned to the kilns, a process that saves fuel and increases burning efficiency.

Grinding and Blending of Clinker to Produce Cement

The clinker is ground to a fine powder and mixed with gypsum. Based on the type of cement to be produced, the clinker and other aggregates will be mixed together in an appropriate proportion. This mixture will then be fed into the cement grinding mill to be ground to the required fineness.